Understanding 2 steel pipe sizes and rules is important. These details help you pick the right 2 steel pipe for your job. Size, like width and wall thickness, shows the pipe’s strength. Rules make sure the 2 steel pipe is safe and of good quality. Knowing this helps you avoid big mistakes and save money. It also ensures success in building, plumbing, or factory work.

Key Takeaways

Learn the difference between size names and real measurements. A 2-inch pipe is actually 2.375 inches wide outside. Always check both to pick the correct pipe.

Know about pipe schedules. Bigger schedule numbers mean thicker, stronger walls. Use Schedule 40 for normal jobs and Schedule 80 for high-pressure work.

Follow rules like ASTM and ANSI. These make sure pipes are safe and good quality. Always buy certified pipes from trusted sellers.

Think about how you’ll use the pipe. For plumbing, Schedule 40 usually works well. For factories, use Schedule 80 or 160 for higher pressure.

Pick good suppliers. Check for certifications and proof of quality. Reliable sellers give you the right pipes fast and without problems.

Key Dimensions of a 2 Steel Pipe

Nominal Size and Actual Dimensions

The term “nominal pipe size” is a standard way to name pipes. But the real size of a 2 steel pipe is different. For instance, a 2-inch pipe has an outside diameter of 2.375 inches (60.3 mm). The wall thickness changes based on the pipe schedule. This schedule decides how strong and heavy the pipe is.

Nominal Size | Outside Diameter (OD) | Wall Thickness (Schedule) |

|---|---|---|

2-inch | 2.375 inches (60.3 mm) | Changes with schedule |

Knowing this difference helps you pick the right pipe. Always check both the nominal size and actual dimensions to match your needs.

Outside Diameter and Inside Diameter

The outside diameter of a 2 steel pipe stays the same for its size. This makes it easy to connect pipes and fittings. The inside diameter, however, depends on the pipe schedule. A thicker wall makes the inside diameter smaller, which affects how much can flow through.

For example, a thicker schedule pipe has a smaller inside diameter than a thinner one. Knowing both diameters helps you decide if the pipe can handle the pressure and flow you need.

Wall Thickness and Its Impact on Strength

The wall thickness of a 2 steel pipe affects its strength and durability. Thicker walls are stronger and can handle more pressure. This makes them good for tough jobs like industrial pipelines or high-pressure systems.

Pipe schedules, like Schedule 40 or Schedule 80, show wall thickness. A higher number means a thicker wall. For example, Schedule 80 pipes are thicker than Schedule 40 pipes of the same size. Picking the right thickness ensures your pipe works well without breaking.

Pipe Schedules and Why They Matter

What Are Pipe Schedules?

Pipe schedules explain how thick a pipe’s wall is. They show how much pressure a pipe can handle and how strong it is. The schedule number, like Schedule 40 or Schedule 80, tells the wall thickness. A bigger number means a thicker wall. This system makes sure pipes are strong and last long for different jobs.

For example, Schedule 40 pipes are used for everyday tasks. Schedule 80 pipes are better for jobs with high pressure, like in factories. Knowing the schedule of a 2-inch steel pipe helps you pick the right one for your work.

Popular Schedules for 2-Inch Steel Pipes

There are many schedules for 2-inch steel pipes. Each one works best for certain uses. The table below shows some common schedules:

Schedule Number | Description | Uses |

|---|---|---|

SCH 40 | Standard thickness for most jobs without high pressure. | General tasks |

SCH 80 | Thicker walls for higher pressure, often in factories. | Industrial tasks |

SCH 160 | Very thick walls for very high-pressure jobs, like in oil plants. | High-pressure jobs |

When choosing a pipe, think about the pressure and strength you need. For homes or small businesses, Schedule 40 is enough. For factories or high-pressure systems, use Schedule 80 or 160.

How Schedules Change Weight and Strength

A pipe’s schedule affects its weight and strength. Thicker walls make pipes heavier, which can be harder to move and install. But thicker walls also make pipes stronger and better at handling pressure. This is why higher schedules are good for tough jobs.

The table below shows how wall thickness and inside diameter change with schedules for a 2-inch pipe:

Pipe Schedule | Wall Thickness | Inside Diameter |

|---|---|---|

Schedule 40 | Thinner | Larger |

Schedule 80 | Thicker | Smaller |

For instance, a Schedule 40 pipe has thinner walls and a bigger inside diameter. This makes it lighter and good for low-pressure jobs. A Schedule 80 pipe has thicker walls and a smaller inside diameter. This makes it stronger and better for high-pressure tasks. By knowing these details, you can pick the right pipe for your job while staying safe and efficient.

Standards for 2 Steel Pipe Dimensions

Key Standards (e.g., ASTM, ANSI, ASME)

When picking a 2-inch steel pipe, make sure it follows rules. These rules decide the pipe’s size, material, and how it works. Three main groups set these rules: ASTM, ANSI, and ASME. They help ensure the pipe is safe and works well for different jobs.

Here’s a simple look at what they do:

Standard | Pipe Size | Description |

|---|---|---|

ANSI | 2-inch | Schedule 40 sizes and details for steel pipes. |

ASTM | 2-inch | A53 pipe rules for pressure and mechanical uses. |

ASME | 2-inch | SA53 pipe for steam, water, gas, and air lines. |

Also, ASTM A530 sets common size limits to keep products consistent. Special rules for each pipe type are more important than general ones. Always check the right rule for your project.

Ensuring Quality and Compatibility

Following rules makes sure your 2-inch steel pipe works as needed. Standards like API Spec 5L and ASTM A53/A53M check the pipe’s strength, quality, and fit with other parts. For example, ASTM A106/A-106M is great for hot jobs, while ASTM A333/A333M works in cold places.

Here’s a list of common pipe rules:

Specification | Description |

|---|---|

API Spec 5L | Rules for Line Pipe |

ASTM A53/A53M | Black and zinc-coated steel pipes, welded or seamless |

ASTM A106/A-106M | Seamless carbon steel pipe for hot jobs |

ASTM A333/A333M | Seamless and welded steel pipe for cold jobs |

ASTM A381 | Welded steel pipe for high-pressure systems |

Choosing pipes that follow these rules ensures they meet your project needs.

Identifying Certified Pipes

To find certified pipes, check for marks or papers showing they follow rules. Certified pipes often have labels like ASTM A53 or ASME SA53. These marks prove the pipe passed tests and meets quality standards.

You can also ask suppliers for proof. Trusted makers, like Angang Metal, give papers showing their pipes meet global rules. This ensures you get pipes that are safe, strong, and fit your project.

Tip: Always buy from trusted sellers with certified pipes. This lowers risks and keeps your project running smoothly.

Applications of 2 Steel Pipes

Uses in Construction and Plumbing

2 steel pipes are strong and useful for many jobs. They work well in water systems, drains, and building frames. These pipes handle pressure and don’t rust easily. This makes them great for homes and businesses. For plumbing, carbon steel pipes move water and gas safely. They last a long time without needing to be replaced often.

In buildings, these pipes support structures or hold electrical wires. Their standard sizes make them easy to install. This saves time and effort. Whether for tall buildings or small homes, 2 steel pipes give strength and dependability.

Industrial Applications (e.g., Oil and Gas, Manufacturing)

Industries like oil and gas use 2 steel pipes a lot. These pipes move liquids and handle high pressure well. Seamless pipes are popular because they work in tough conditions. For example, the U.S. oil industry uses many steel pipes. In December 2023, it made 13.21 million barrels of oil daily. Over half of steel pipe sales come from this industry.

Factories also use these pipes to move chemicals, steam, and air. They are strong and don’t wear out quickly. In Asia-Pacific, demand for seamless pipes is growing fast due to more factories. Whether for energy or machines, these pipes are reliable for hard jobs.

Selecting the Right Pipe for Specific Applications

Picking the right pipe depends on your project’s needs. For low pressure, use Schedule 5 pipes with thin walls. Plumbing and building jobs often need Schedule 40 pipes. These are strong but not too heavy. High-pressure systems, like in factories, need Schedule 80 pipes. For very tough jobs, use Schedule 160 or XXS pipes.

Schedule Number | Wall Thickness | Application Use |

|---|---|---|

5 | Thinnest walls | Low-pressure applications |

40 | Commonly used | Plumbing, structural uses |

80 | Thicker walls | High-pressure applications |

160/XXS | Thickest walls | Extremely high-pressure environments |

Think about things like rust resistance and strength when choosing. Carbon steel pipes are great for strong and tough jobs. By checking these features, you can pick the best pipe for your work.

Choosing the Right 2 Steel Pipe

Understanding Your Project’s Needs

To pick the right 2-inch steel pipe, know your project needs. Think about pressure, temperature, and what the pipe will carry. For example, plumbing pipes should resist rust. Industrial pipes must handle high pressure and heat.

Also, consider where the pipe will be used. Outdoor pipes may need a galvanized coating to stop rust. Indoor pipes can use carbon steel, which is strong and reliable. Knowing these details early helps avoid mistakes and keeps your project on track.

Comparing Sizes, Schedules, and Rules

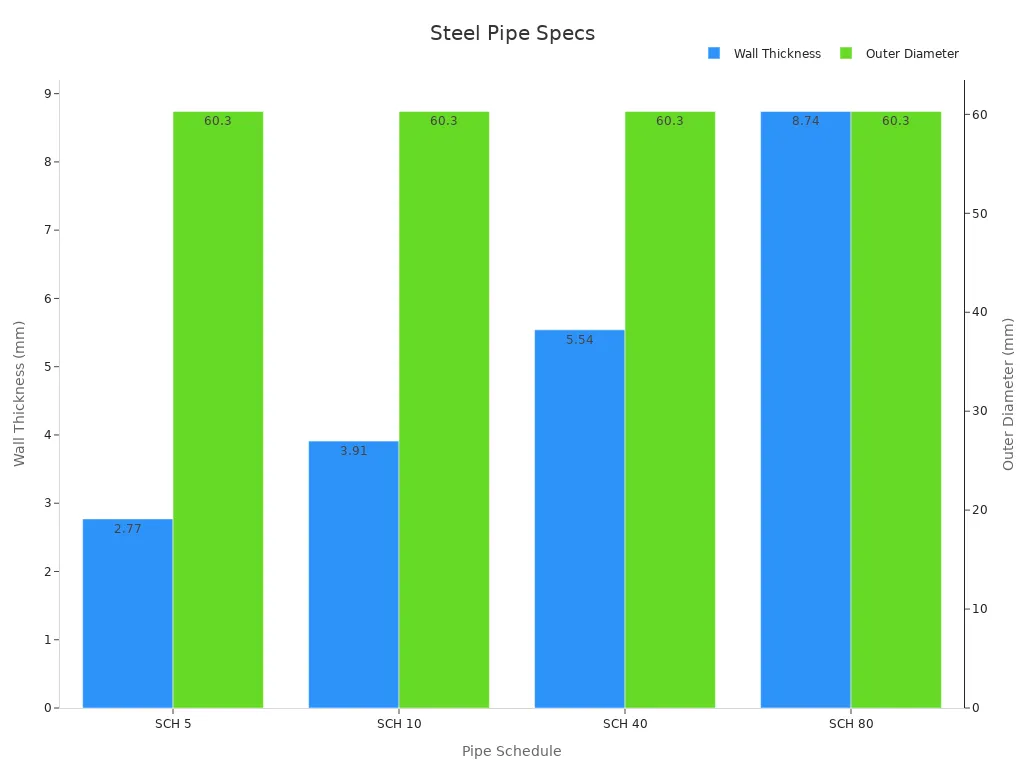

Pipe size, schedule, and rules are important when choosing. The schedule shows how thick the pipe walls are. Thicker walls mean stronger pipes. For example, Schedule 40 pipes work for most jobs. Schedule 80 pipes are better for high-pressure tasks. The table below shows how wall thickness changes by schedule:

Schedule | Wall Thickness (WT) | Outer Diameter (OD) |

|---|---|---|

SCH 5 | 2.77 mm | 60.3 mm |

SCH 10 | 3.91 mm | 60.3 mm |

SCH 40 | 5.54 mm | 60.3 mm |

SCH 80 | 8.74 mm | 60.3 mm |

Rules like ASTM and ASME make sure pipes are safe and high quality. Certified pipes are more dependable and fit well with other parts. The chart below shows how wall thickness changes with schedules:

Tips for Choosing Good Suppliers

Working with a trusted supplier ensures you get good pipes. Look for suppliers with certifications like ISO or CE. These show they follow global rules. Reliable suppliers, like Angang Metal, give proof their pipes meet industry standards.

Ask about their stock and delivery options. Suppliers with big inventories, like Angang Metal’s 5,000,000-ton yearly supply, can deliver fast. Also, choose suppliers offering extra services like cutting or transport. These save time and make your project easier.

Tip: Always ask for certifications and test reports to check pipe quality.

Knowing about pipe sizes, schedules, and rules is very important. These details show how strong and long-lasting your 2-inch steel pipe is. They also help ensure your project works well.

Tip: Always check if the pipe fits your project’s needs. Think about pressure, heat, and if the material works well.

When choosing a pipe, pick certified ones from trusted sellers like Angang Metal. Check for worldwide certifications and proper papers. This makes sure you get strong, high-quality pipes that work well for any job.

FAQ

What is the outside diameter of a 2-inch steel pipe?

A 2-inch steel pipe has an outside diameter of 2.375 inches. This size stays the same no matter the pipe’s schedule or thickness.

How does a pipe’s schedule affect its strength?

The schedule shows how thick the pipe walls are. Higher schedules, like Schedule 80, have thicker walls. Thicker walls make the pipe stronger and handle more pressure.

Can 2-inch steel pipes be used indoors and outdoors?

Yes, 2-inch steel pipes work for both indoor and outdoor jobs. For outdoor use, galvanized pipes are best because they resist rust and damage.

What standards should you check when buying a 2-inch steel pipe?

Check for standards like ASTM, ANSI, or ASME. These ensure the pipe is good quality, the right size, and works well for your project.

How do you pick the right 2-inch steel pipe for plumbing?

For plumbing, use a Schedule 40 pipe for normal water systems. If the system has high pressure, pick a Schedule 80 pipe for extra strength.