Steel pipes play a crucial role in various industries. IL 2 inch steel pipe stands out as a popular choice due to its strength and versatility. With a size of 2 inches and an outside diameter of 60.3 mm, the 2 inch steel pipe is designed to meet diverse needs. These pipes come in different weights depending on their type. Ad esempio, Schedule 40 pipes weigh 1.65 lbs/ft, while heavier options can weigh up to 7.49 lbs/ft. Understanding these specifications ensures you select the right 2 inch steel pipe for your project, guaranteeing optimal performance and durability, even in challenging environments.

Punti chiave

Learn about 2 inch steel pipes’ size, weight, and thickness. This helps you pick the right pipe for your project.

Choose the best material for your needs. Carbon steel is cheap, stainless steel doesn’t rust, and alloy steel handles heat and pressure well.

Understand welded and seamless pipes. Welded pipes cost less and work for low pressure. Seamless pipes are stronger for high pressure.

Check pressure ratings and wall thickness when picking a pipe. Thicker walls are stronger for high-pressure systems.

Use coatings like galvanization or epoxy to stop rust. This makes pipes last longer, especially in tough conditions.

Specifications of 2 Inch Steel Pipe

Dimensions and Sizing Standards for Steel Pipe

Knowing the size of a 2 inch steel pipe is important. IL “2 inch” size is called the nominal pipe size (NPS). This is a global standard for naming pipe sizes. But, the real outside diameter (OD) of a 2 inch steel pipe is 60.3 mm. This size follows rules like ASME B36.10M and ASME B36.19M. These rules also decide the wall thickness, which changes with the pipe schedule. Per esempio, Schedule 40 pipes have walls 3.91 mm di spessore. Schedule 80 pipes are thicker, with walls of 5.54 mm.

Here’s a simple table to compare sizing standards:

Standard | Descrizione |

|---|---|

ASME B36.10M | Lists sizes for seamless and welded steel pipes. |

ASME B36.19M | Focuses on stainless steel pipe sizes. |

NPS | Names pipe sizes, mainly for pipes smaller than NPS 12. |

Schedule | Shows pipe wall thickness, like Schedule 40 or 80. |

Always check the pipe size and schedule to match your project needs.

Material Grades Commonly Used in 2 Inch Steel Pipe

The material of a steel pipe affects its strength and use. Common materials for 2 inch steel pipes are carbon steel, stainless steel, and alloy steel. Each has special features:

Carbon Steel: Strong and affordable, it works well for buildings and factories. Lo ha fatto up to 0.24% carbonio e 1.35% manganese.

Stainless Steel: Resists rust, so it’s great for plumbing and chemicals. Standards like ASTM A312 and ASTM A269 apply to it.

Alloy Steel: Stronger for high heat and pressure, it’s used in tough jobs. ASTM A213 is a common rule for this type.

Pick the right material based on your project’s needs and environment.

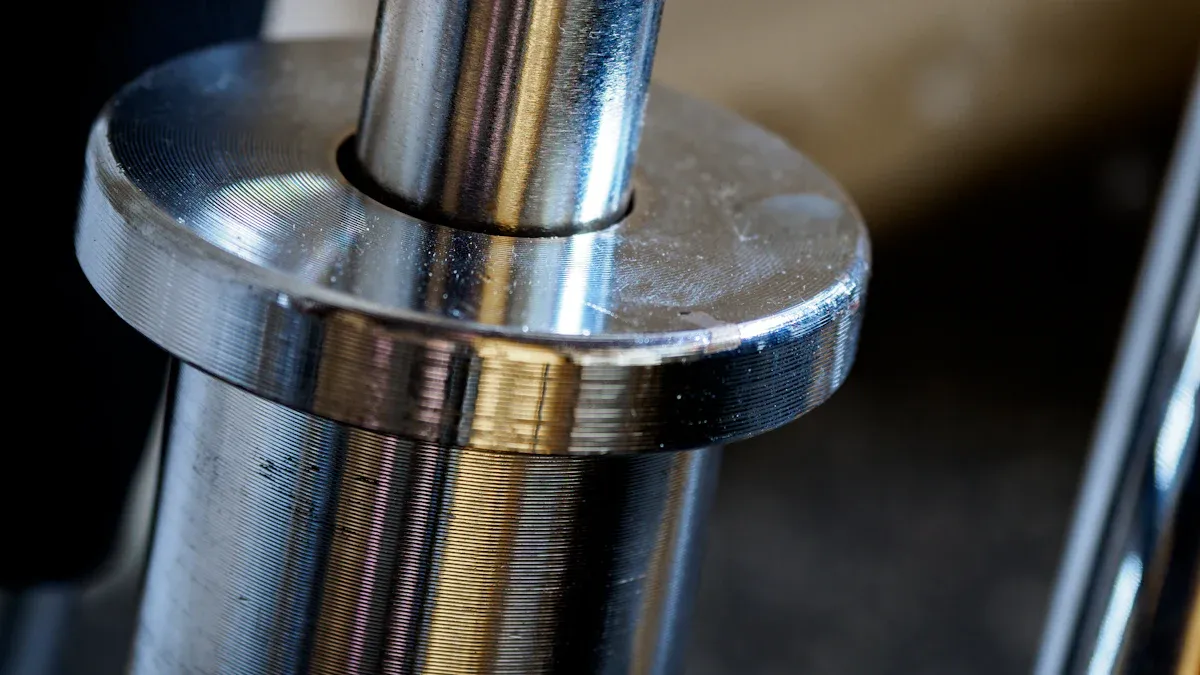

Manufacturing Types: Welded vs. Seamless Steel

How a steel pipe is made affects its cost and strength. There are two main types: welded and seamless pipes. Each has its own benefits:

Welded Steel Pipes: Made by rolling steel into a tube and welding it. They are cheaper and good for low-pressure jobs. ASME B36.10M sets their size and quality rules.

Seamless Steel Pipes: Made without welding, they are stronger and more reliable. They work well in high-pressure and hot conditions, like oil pipelines. ASTM A213 and ASTM A312 guide their production.

Both types are tested for quality using methods like ultrasonic and X-ray tests. Choose welded or seamless pipes based on strength, pressure needs, and budget.

Pressure Ratings and Wall Thickness of Steel Pipes

When picking a steel pipe, know its pressure rating and wall thickness. These decide how much pressure the pipe can handle and how strong it is. Thicker walls make pipes stronger and better for high-pressure jobs.

Steel pipes are grouped by schedules, which show wall thickness. Ad esempio, Schedule 40 pipes have medium-thick walls. Schedule 80 and Schedule 160 pipes have thicker walls for higher pressure. Below is a table with pressure ratings for 2 inch steel pipes:

Pipe Schedule | PSI Rating (approximate) |

|---|---|

Schedule 40 | 700-2,000 PSI |

Schedule 80 | 1,200-3,000 PSI |

Schedule 160 | 2,500-6,000 PSI |

Pick the right schedule based on your pressure needs. Schedule 40 works for low-pressure systems. High-pressure systems, like in factories or oil jobs, may need Schedule 80 or 160. Always check the pressure rating to match your project.

Thicker walls also mean heavier and pricier pipes. But they are stronger and last longer. Think about weight, costo, and strength when choosing a pipe.

Corrosion Resistance: Coatings and Treatments for Steel Pipes

Rust can shorten a steel pipe’s life. To stop this, pipes get special coatings or treatments. These protect against rust, prodotti chimici, and harsh weather. This is key for pipes in wet or tough conditions.

Common coatings include:

Galvanization: A zinc layer stops rust. Great for outdoor and plumbing use.

Epoxy Coatings: Tough layers block rust and chemical harm. Used in factories and near water.

Polyethylene (PE) Coatings: Plastic layers fight moisture and scratches. Good for buried pipes.

Other treatments, like cathodic protection, add more durability. This uses electricity to stop rust, often for underground or underwater pipes.

Think about where the pipe will be used. For harsh environments, pick pipes with strong coatings or treatments. This keeps them working longer and lowers repair costs.

Applications of 2 Inch Steel Pipe

Construction and Structural Steel Applications

2 inch steel pipes are often used in building projects. They are strong and durable, making them great for frameworks and scaffolding. These pipes are also used in bridges, foundations, and tall buildings. Their strength helps keep structures safe and stable.

These pipes are easy to cut, saldare, and shape. This makes them useful for different designs. Architects and engineers like using them for many projects. From homes to big infrastructure, steel pipes are a reliable choice. Angang Metal Products offers custom options for your construction needs.

Plumbing, Water Systems, and Drainage

Steel pipes are important for plumbing and water systems. A 2 inch steel pipe is great for moving water, sewage, and liquids. It resists rust, so it lasts longer in wet places. Galvanized steel pipes are especially good for plumbing since they keep water clean.

These pipes are also used in drainage systems. They can handle high water pressure and heavy flow. This makes them useful for homes and factories. With the right fittings, they connect easily and prevent leaks. Angang Metal’s pipes meet modern plumbing needs.

Industrial Uses for 2 Inch Steel Pipe

Industries use steel pipes for many jobs. A 2 inch steel pipe works in factories, chemical plants, and farms. It handles high heat and pressure, making it good for moving gases and chemicals.

In farming, these pipes are used for irrigation and support structures. They are tough enough for outdoor use. Factories also use them in machines and conveyor systems. Angang Metal has many options to fit your industrial needs.

Mancia: When choosing a steel pipe for industry, check pressure ratings, rust resistance, and fitting compatibility for the best results.

Oil and Gas Pipelines

The oil and gas industry uses steel pipes a lot. They move crude oil, natural gas, and other products. A 2 inch steel pipe is great for small pipelines. It is strong and handles high pressure and heat well. Coatings like epoxy or polyethylene stop rust, making it last longer.

Steel pipes here must follow strict rules like API 5L. This ensures they work well for oil and gas transport. Seamless pipes are stronger and more reliable. They are used in tough jobs like offshore drilling. Welded pipes cost less and are good for easier tasks.

When picking a pipe, think about pressure, heat, and the fluid type. Regular checks and care keep pipelines safe and working well.

HVAC and Fire Protection Systems

A 2 inch steel pipe is key in HVAC and fire systems. In HVAC, it moves water, steam, or refrigerants. It handles high pressure and heat, making it useful for homes and businesses. Galvanized pipes stop rust, so they last longer.

In fire systems, steel pipes are very important. They are used in sprinklers, hydrants, and other parts. One project replaced PVC pipes with steel ones to meet rules. It had 42 hydrants and 3256 meters of pipe. Software checked the system to keep flow and pressure right. Steel pipes proved strong and reliable for fire safety.

When choosing pipes for HVAC or fire systems, check rust resistance and pressure ratings. Follow rules and maintain them to keep systems safe and efficient.

How to Select the Right 2 Inch Steel Pipe

Evaluating Project Needs for Steel Pipes

Choosing the right steel pipe starts with knowing your project’s needs. Think about what the pipe will do and how it will perform. Follow these steps to make the best choice:

Pick the Pipe Type: Decide if you need welded or seamless pipes. Welded pipes are cheaper and good for low-pressure jobs. Seamless pipes are stronger and better for high-pressure tasks.

Choose the Right Size: Match the pipe’s size and schedule to your project. Per esempio, UN 2 inch steel pipe with Schedule 40 works well for medium-pressure systems.

Select the Material Grade: Pick a material that fits your project. Carbon steel is great for building, while stainless steel resists rust in plumbing and chemical uses.

Anche, check things like wall thickness, alignment, and diameter. Use tools to measure these details carefully. This ensures the pipe meets modern standards and works well in tough conditions.

Key Differences Between Welded and Seamless Steel Pipes

Knowing how welded and seamless pipes differ helps you choose wisely. Each type has its own strengths for different jobs.

Welded Steel Pipes: These are made by rolling steel into a tube and welding it. They cost less and are good for low-pressure systems like HVAC or drainage. Welded pipes are easy to make in large amounts, saving money for simpler projects.

Seamless Steel Pipes: These are made without welding, so they are stronger and last longer. They work well in high-pressure jobs like oil pipelines or factories. Seamless pipes also hold their shape under tough conditions.

Think about pressure, heat, and the type of fluid when choosing. Seamless pipes are better for hard jobs, while welded pipes are fine for easier ones.

Mancia: For high heat or corrosive fluids, seamless pipes are often the best choice because they are tougher.

Durability and Environmental Considerations

Durability matters when picking steel pipes, especially for harsh environments. Look at how the pipe’s material and coatings handle wear and tear. Here are some tips:

Material Choice: Galvanized steel fights rust, making it great for outdoor use. Stainless steel lasts longer in wet or chemical-heavy places. Alloy steel is super strong for extreme conditions.

Coatings and Treatments: Coatings like epoxy or polyethylene protect pipes from rust and damage. Galvanized pipes are perfect for plumbing and water systems.

Environmental Impact: Studies show galvanized and stainless steel pipes resist rust in salty or wet places. These materials last longer, cutting down on repairs and waste.

By thinking about these factors, you can pick a pipe that’s strong, durable, and eco-friendly. Regular checks and care keep pipes working well and save money on fixes.

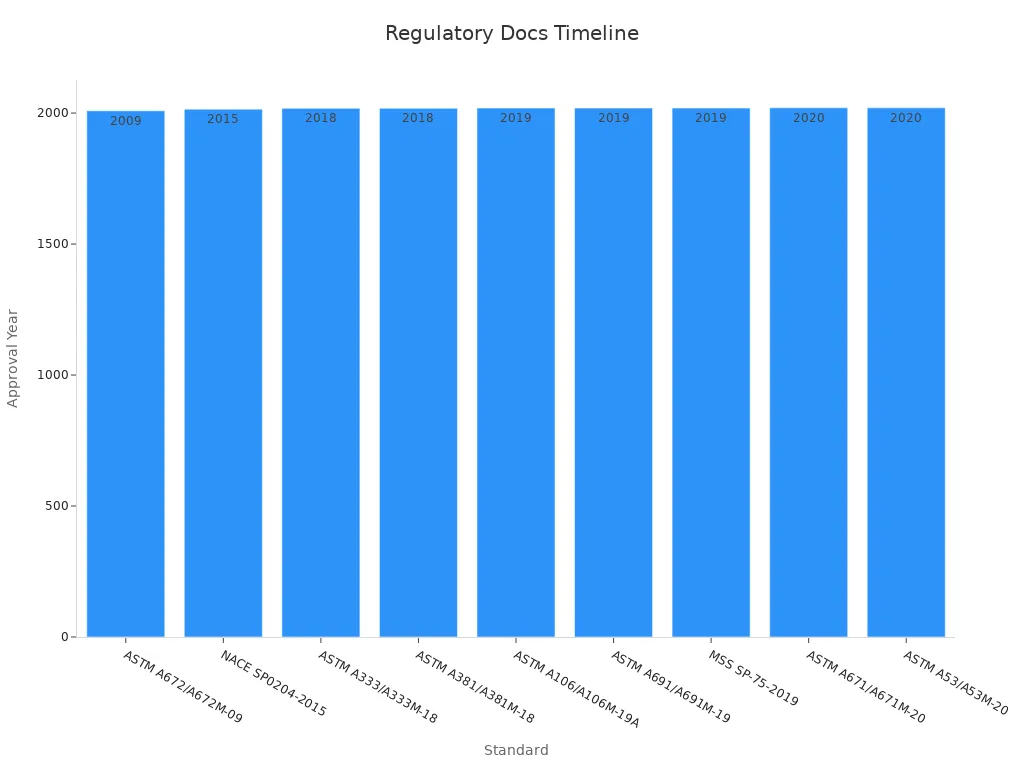

Meeting Industry Standards for Steel Pipe

Picking the right steel pipe means following industry standards. These rules make sure pipes are safe, forte, and durable. They also help pipes work well under tough conditions like high pressure, heat, or rust.

Many global standards apply to 2 inch steel pipes. ASTM rules explain how pipes are made, tested, and what materials are used. Below is a table showing key ASTM standards:

Standard | Descrizione | Approval Date |

|---|---|---|

ASTM A106/A106M-19A | Seamless Carbon Steel Pipe for High-Temperature Service | November 1, 2019 |

ASTM A333/A333M-18 | Seamless and Welded Steel Pipe for Low-Temperature Service | November 1, 2018 |

ASTM A381/A381M-18 | Metal-Arc-Welded Carbon or High-Strength Low-Alloy Steel Pipe | November 1, 2018 |

ASTM A671/A671M-20 | Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures | March 1, 2020 |

ASTM A672/A672M-09 | Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures | October 1, 2009 |

ASTM A691/A691M-19 | Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures | November 1, 2019 |

These standards help you pick the right pipe for your job. Per esempio, ASTM A106/A106M-19A works for hot conditions, while ASTM A333/A333M-18 is better for cold places. Following these rules ensures the pipe is strong and lasts long.

Groups like ASTM and MSS also provide documents to check if pipes meet standards. IL chart below shows when different standards were approved, showing how rules have changed over time:

Always check if a pipe meets the right standards. This ensures it works well and follows safety rules.

Cost vs. Performance Trade-offs in Pipe Selection

Choosing a steel pipe means balancing cost and performance. Cheaper pipes may seem good, but they can cost more later if they fail.

Here’s what to think about when comparing cost and performance:

Material Selection: Carbon steel pipes cost less and work for basic jobs. Stainless steel pipes cost more but resist rust and last longer, making them great for plumbing or chemicals.

Manufacturing Type: Welded pipes are cheaper and good for low-pressure systems. Seamless pipes are stronger and better for high-pressure or hot conditions.

Coatings and Treatments: Coated pipes, like galvanized or epoxy ones, cost more upfront but last longer, saving money on repairs.

Pipe Schedule: Thicker pipes, like Schedule 80 or 160, cost more but handle higher pressure and last longer.

Per esempio, if you’re moving corrosive liquids, a stainless steel pipe with epoxy coating costs more but prevents leaks and lasts longer. For low-pressure systems, a welded carbon steel pipe is cheaper and works fine.

Mancia: Think about total costs, like installation, repairs, and downtime, not just the price tag.

By weighing these factors, you can pick a pipe that fits your needs and budget.

Knowing about 2 inch steel pipes helps ensure safety and performance. These pipes are strong and useful in many industries like building, plumbing, ed energia.

Understanding details like size, thickness, and material helps you choose the right pipe. This ensures it works well and lasts long in different systems.

Always ask experts and follow rules to get the best results for your project.

Domande frequenti

What’s the difference between Schedule 40 and Schedule 80 tubi?

Schedule 40 pipes have thinner walls and weigh less. They are good for low-pressure systems. Schedule 80 pipes have thicker walls, making them stronger. They handle higher pressure and last longer. Pick based on your system’s needs.

Can 2 inch steel pipes go underground?

SÌ, you can use 2 inch steel pipes underground. Choose pipes with rust-proof coatings like galvanization or polyethylene. These coatings protect pipes from water and soil damage.

How do you check the size of a 2 inch steel pipe?

The size is called the nominal pipe size (NPS). It’s not the actual diameter. A 2 inch steel pipe has an outside diameter of 60.3 mm. Always check the NPS and schedule for correct sizing.

Are seamless pipes better than welded ones?

Seamless pipes are stronger and work well under high pressure or heat. Welded pipes cost less and are fine for low-pressure jobs. Choose based on what your project needs.

Which coatings stop rust the best?

Galvanization, epoxy, and polyethylene coatings are great for stopping rust. Galvanized pipes are good for outdoor use. Epoxy and polyethylene coatings work well in factories or underground.

Mancia: Pick a coating that fits the environment to make pipes last longer.